工業涂裝流水線安裝過程會用到什么設備

在工業生產中,產品的涂裝不僅關乎美觀,更對其耐候性、防腐蝕性等性能起著關鍵作用。一條設計合理、安裝精良的涂裝流水線,能夠大幅提升涂裝效率與質量,為企業創造顯著的經濟效益。然而,工業涂裝流水線的安裝并非易事,它涉及多個復雜環節與專業領域,需要嚴謹規劃與精細操作。

In industrial production, the coating of products not only affects their appearance, but also plays a key role in their weather resistance, corrosion resistance, and other properties. A well-designed and well-equipped painting assembly line can significantly improve painting efficiency and quality, creating significant economic benefits for enterprises. However, the installation of industrial painting assembly lines is not an easy task, as it involves multiple complex links and professional fields, requiring rigorous planning and precise operation.

一、基礎施工

1、 Basic construction

基礎施工是保障涂裝流水線穩定運行的根基。對于大型設備,如烘干室、大型噴涂房,需澆筑堅固的混凝土基礎,確保設備安裝后不會因地面沉降而發生位移、傾斜。基礎的尺寸、平整度、預埋螺栓位置等都要嚴格按照設備安裝圖紙要求施工。在基礎養護期結束后,對基礎表面進行平整度檢測,誤差控制在規定范圍內。同時,檢查預埋螺栓的緊固程度與垂直度,為后續設備安裝提供堅實基礎。

Basic construction is the foundation for ensuring the stable operation of the painting assembly line. For large equipment such as drying rooms and spraying rooms, a sturdy concrete foundation needs to be poured to ensure that the equipment will not be displaced or tilted due to ground settlement after installation. The dimensions, flatness, and pre embedded bolt positions of the foundation must be strictly constructed according to the requirements of the equipment installation drawings. After the end of the basic maintenance period, the flatness of the foundation surface shall be tested, and the error shall be controlled within the specified range. At the same time, check the tightness and verticality of the embedded bolts to provide a solid foundation for subsequent equipment installation.

二、設備安裝與調試

2、 Equipment installation and debugging

1.輸送系統安裝:輸送系統是涂裝流水線的 “動脈”,負責產品在各工序間的流轉。常見的輸送方式有懸掛式輸送鏈、地面滑橇輸送等。以懸掛式輸送鏈安裝為例,首先安裝軌道,確保軌道的直線度、水平度符合要求,軌道接頭處光滑過渡,避免產品運行時出現卡頓。安裝驅動裝置與張緊裝置,調整鏈條的松緊度,使其在運行過程中平穩無晃動。安裝完成后,進行空載試運行,檢查鏈條運行是否順暢、有無跑偏現象,及時調整偏差。

1. Installation of Conveyor System: The conveyor system is the "artery" of the painting assembly line, responsible for the flow of products between various processes. Common transportation methods include suspended conveyor chains, ground sled transportation, etc. Taking the installation of a suspended conveyor chain as an example, the first step is to install the track, ensuring that the straightness and levelness of the track meet the requirements, and that the track joints transition smoothly to avoid product jamming during operation. Install the driving device and tensioning device, adjust the tightness of the chain to ensure smooth and stable operation without shaking. After installation, conduct a no-load trial run to check if the chain runs smoothly and if there is any deviation, and adjust the deviation in a timely manner.

2.噴涂設備安裝:噴涂設備是涂裝流水線的核心部分。安裝噴槍時,根據產品形狀、尺寸及涂裝工藝要求,確定噴槍的安裝位置與角度,保證噴涂均勻覆蓋產品表面。連接噴槍與涂料輸送管道,確保管道密封良好,無泄漏風險。安裝噴涂房,噴涂房應具備良好的通風換氣系統,防止漆霧積聚。通風管道的安裝要注意坡度,避免冷凝水積聚影響通風效果。安裝完成后,對噴涂設備進行調試,調節噴槍的噴涂壓力、流量、霧化效果等參數,通過試噴樣板件,檢查涂層厚度、均勻度等質量指標,直至達到理想效果。

2. Installation of spraying equipment: Spraying equipment is the core part of the painting assembly line. When installing the spray gun, determine the installation position and angle of the spray gun according to the shape, size, and coating process requirements of the product to ensure even coverage of the product surface. Connect the spray gun to the paint delivery pipeline to ensure good sealing and no risk of leakage. Install a spray booth, which should have a good ventilation system to prevent the accumulation of paint mist. The installation of ventilation ducts should pay attention to the slope to avoid the accumulation of condensed water affecting the ventilation effect. After installation, debug the spraying equipment, adjust the spraying pressure, flow rate, atomization effect and other parameters of the spray gun, and check the quality indicators such as coating thickness and uniformity through trial spraying of sample pieces until the desired effect is achieved.

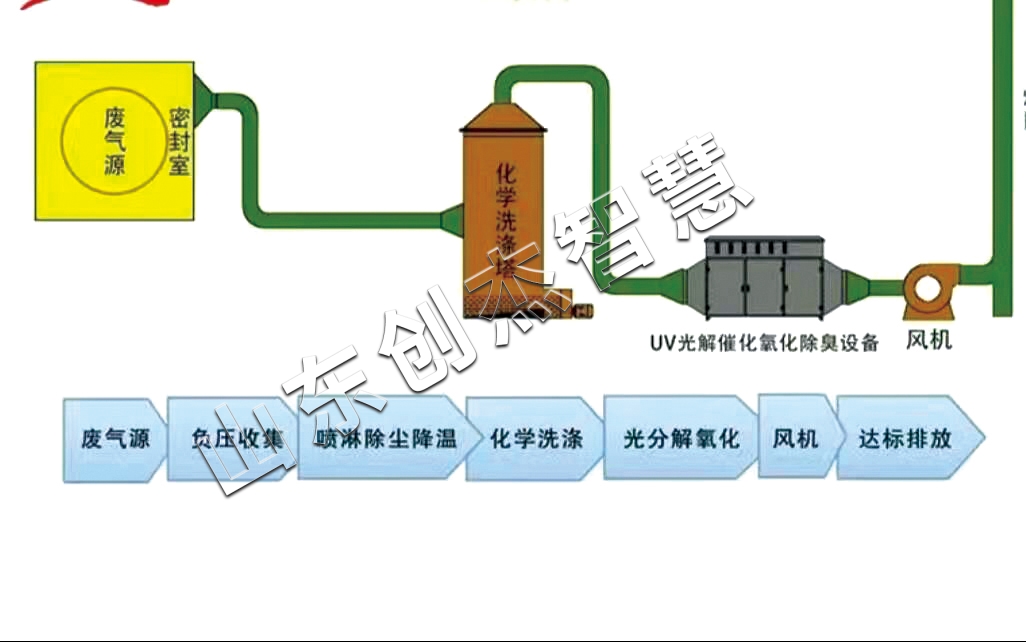

3.烘干設備安裝:烘干設備用于固化涂層,提升涂層的附著力與性能。安裝烘干室時,確保其保溫性能良好,墻體、門等部位的密封嚴密,減少熱量散失。安裝加熱裝置,如電加熱元件、燃氣燃燒器等,連接好供熱管道與控制系統。調試烘干室的溫度控制系統,設置升溫曲線、保溫時間等參數,通過實際測試,驗證溫度控制精度是否滿足涂裝工藝要求。同時,檢查烘干室的廢氣排放系統,確保廢氣達標排放。

3. Installation of drying equipment: The drying equipment is used to cure the coating, improve the adhesion and performance of the coating. When installing the drying room, ensure good insulation performance, tight sealing of walls, doors, and other parts to reduce heat loss. Install heating devices such as electric heating elements, gas burners, etc., and connect the heating pipeline and control system. Debug the temperature control system of the drying room, set parameters such as temperature rise curve and insulation time, and verify through actual testing whether the temperature control accuracy meets the requirements of the coating process. At the same time, check the exhaust emission system of the drying room to ensure that the exhaust emissions meet the standards.

預處理設備安裝:預處理設備用于清潔產品表面,去除油污、鐵銹等雜質,為后續涂裝提供良好的基底。安裝脫脂槽、酸洗槽、磷化槽等設備時,要確保槽體的密封性,防止液體泄漏。連接循環泵、過濾器等輔助設備,保證預處理液的循環與過濾效果。調試預處理設備的溫度控制系統、液位控制系統,確保各工藝參數穩定在規定范圍內。

Installation of pre-treatment equipment: The pre-treatment equipment is used to clean the surface of the product, remove impurities such as oil and rust, and provide a good substrate for subsequent coating. When installing equipment such as degreasing tanks, acid pickling tanks, phosphating tanks, etc., it is necessary to ensure the sealing of the tank body to prevent liquid leakage. Connect auxiliary equipment such as circulation pumps and filters to ensure the circulation and filtration effect of the pre-treatment solution. Debug the temperature control system and liquid level control system of the pre-processing equipment to ensure that all process parameters remain stable within the specified range.

三、電氣與控制系統安裝

3、 Installation of Electrical and Control Systems

電氣與控制系統是涂裝流水線的 “大腦”,控制設備的運行、參數調節及故障報警等。鋪設電氣線路時,嚴格按照電氣安裝規范操作,確保線路整齊、牢固,絕緣良好。安裝控制柜,將各類電氣元件、控制器安裝在控制柜內,進行布線與接線。調試控制系統,編寫控制程序,實現設備的自動化運行,如按設定的工藝流程自動啟動、停止各設備,根據產品類型自動調整涂裝參數等。設置故障報警功能,當設備出現異常時,能及時發出聲光報警信號,提示操作人員進行處理。

The electrical and control system is the "brain" of the painting assembly line, controlling the operation, parameter adjustment, and fault alarm of the equipment. When laying electrical circuits, strictly follow the electrical installation specifications to ensure that the circuits are neat, secure, and have good insulation. Install the control cabinet, install various electrical components and controllers inside the control cabinet, and perform wiring and connection. Debug the control system, write control programs, and achieve automated operation of equipment, such as automatically starting and stopping each device according to the set process flow, and automatically adjusting coating parameters according to product types. Set up a fault alarm function, which can promptly emit sound and light alarm signals when the equipment encounters abnormalities, prompting operators to take action.

工業涂裝流水線的安裝是一項系統工程,從前期規劃到安裝實施,再到驗收與維護,每個環節都緊密相連,關乎流水線的運行效果與企業的生產效益。通過嚴謹的規劃、精細的安裝與持續的維護,打造出高效、優質、環保的涂裝流水線,為企業的產品涂裝質量與市場競爭力提供堅實保障。?

The installation of industrial painting assembly line is a systematic project, from early planning to installation implementation, to acceptance and maintenance, each link is closely connected, which is related to the operation effect of the assembly line and the production efficiency of the enterprise. Through rigorous planning, meticulous installation, and continuous maintenance, we have created an efficient, high-quality, and environmentally friendly coating assembly line, providing a solid guarantee for the coating quality and market competitiveness of our products. ?

本文由工業涂裝流水線友情奉獻.更多有關的知識請點擊:http://www.gtjjw.cn我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

上一篇:工業涂裝流水線的發展提供了哪些技術?

下一篇:為什么建議使用機器人自動噴粉線?

魯公網安備 37142502000144號

魯公網安備 37142502000144號