機器人涂裝線材質解析

在現代化工業生產中,機器人涂裝線以其高效、精準、穩定的特點,廣泛應用于汽車、家電、3C電子、航空航天等多個領域。涂裝線作為產品表面處理的關鍵環節,其材質的選擇直接關系到涂裝質量、生產效率以及設備的使用壽命。本文將詳細解析機器人涂裝線各組成部分所使用的材質及其優勢。

In modern industrial production, robot painting lines are widely used in various fields such as automobiles, home appliances, 3C electronics, aerospace, etc. due to their high efficiency, precision, and stability. The material selection of the coating line, as a key link in product surface treatment, directly affects the coating quality, production efficiency, and equipment service life. This article will provide a detailed analysis of the materials and advantages used in each component of the robot painting line.

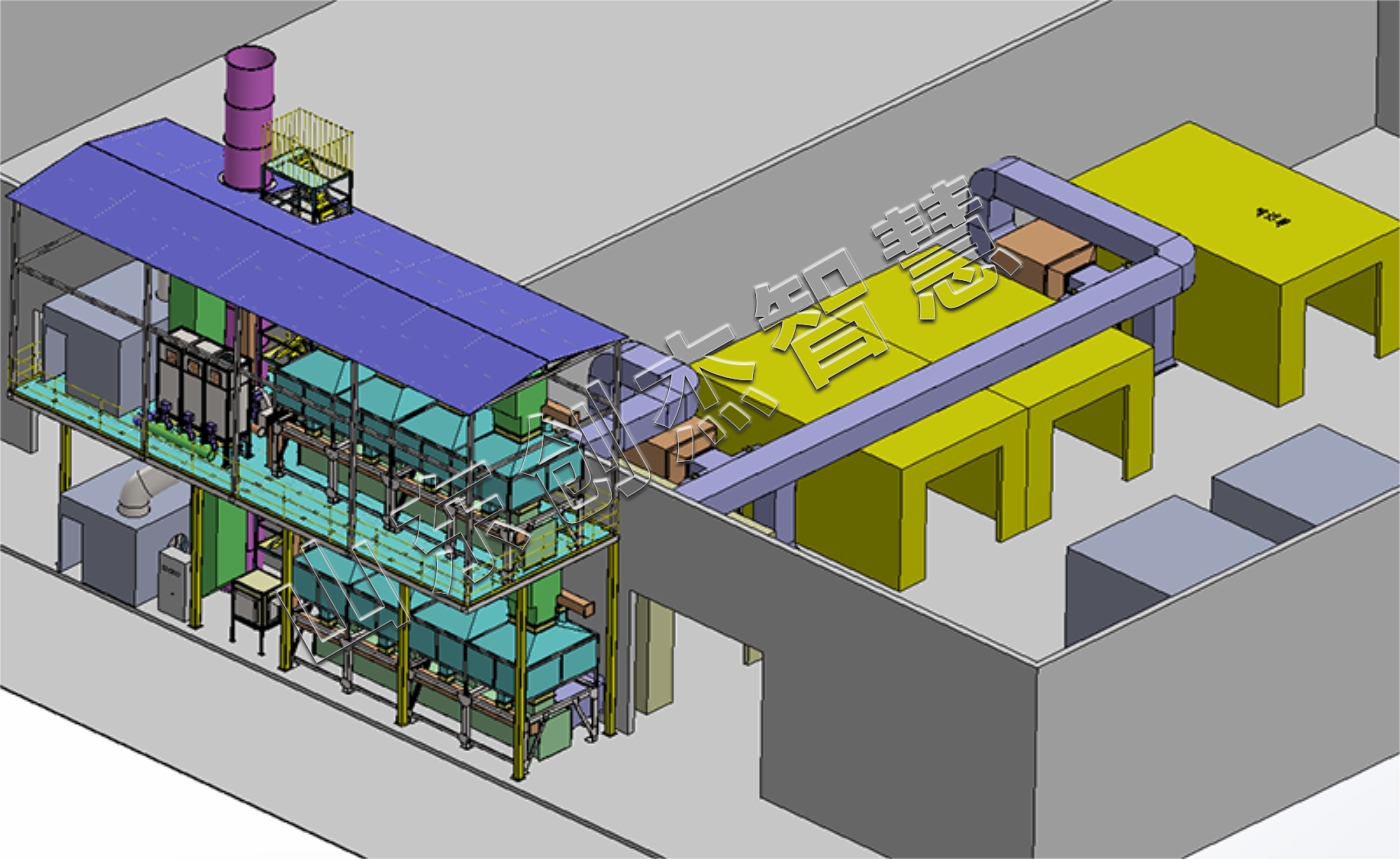

機器人涂裝線主要由機器人本體、涂裝設備、輸送系統、控制系統和安全防護裝置等部分組成。

The robot painting line mainly consists of the robot body, painting equipment, conveying system, control system, and safety protection device.

1. 機器人本體材質

1. Material of robot body

機器人本體是涂裝線的核心執行部件,負責完成噴涂、涂膠、打磨等復雜工藝。其材質的選擇需兼顧強度、剛性、輕量化和耐腐蝕性。

The robot body is the core executing component of the painting line, responsible for completing complex processes such as spraying, gluing, and polishing. The selection of its material should take into account strength, rigidity, lightweight, and corrosion resistance.

鋁合金:鋁合金因其密度低、強度高、耐腐蝕性好,成為機器人本體結構的首選材質。它能夠有效減輕機器人自重,提高運動速度和加速度,同時保證足夠的結構強度,確保噴涂過程中的穩定性和精度。

Aluminum alloy: Aluminum alloy has become the preferred material for robot body structures due to its low density, high strength, and good corrosion resistance. It can effectively reduce the weight of the robot, improve its movement speed and acceleration, while ensuring sufficient structural strength and stability and accuracy during the spraying process.

碳纖維復合材料:在高端機器人涂裝線中,碳纖維復合材料也逐漸得到應用。碳纖維具有極高的比強度和比剛度,能夠進一步減輕機器人重量,提高動態響應性能,同時具備良好的耐疲勞性和耐腐蝕性,適用于高精度、高速度的噴涂作業。

Carbon fiber composite materials: In high-end robot painting lines, carbon fiber composite materials are gradually being applied. Carbon fiber has extremely high specific strength and stiffness, which can further reduce the weight of robots, improve dynamic response performance, and have good fatigue and corrosion resistance. It is suitable for high-precision and high-speed spraying operations.

2. 涂裝設備材質

2. Coating equipment material

涂裝設備包括噴槍、供漆系統、霧化裝置等,其材質需滿足耐化學腐蝕、耐磨、耐高溫等要求,以確保涂裝質量和設備穩定性。

Painting equipment includes spray guns, paint supply systems, atomization devices, etc., and their materials must meet requirements such as chemical corrosion resistance, wear resistance, and high temperature resistance to ensure painting quality and equipment stability.

不銹鋼:不銹鋼因其優異的耐腐蝕性和耐磨性,成為涂裝設備的主要材質。特別是在供漆系統、管道、閥門等部件中,不銹鋼能夠有效防止涂料中的化學物質對設備的腐蝕,延長設備使用壽命。

Stainless steel: Stainless steel has become the main material for painting equipment due to its excellent corrosion resistance and wear resistance. Especially in paint supply systems, pipelines, valves and other components, stainless steel can effectively prevent chemical substances in the coating from corroding the equipment and extend its service life.

工程塑料:在噴槍、霧化裝置等部件中,工程塑料因其良好的耐化學性、耐磨性和絕緣性得到廣泛應用。例如,聚醚醚酮(PEEK)、聚四氟乙烯(PTFE)等高性能工程塑料,能夠耐受高溫、高壓和強腐蝕性的涂料,保證噴涂過程的穩定性和涂層質量。

Engineering plastics: Engineering plastics are widely used in components such as spray guns and atomization devices due to their excellent chemical resistance, wear resistance, and insulation properties. For example, high-performance engineering plastics such as polyetheretherketone (PEEK) and polytetrafluoroethylene (PTFE) can withstand high temperature, high pressure, and strong corrosive coatings, ensuring stability and coating quality during the spraying process.

3. 輸送系統材質

3. Material of the conveying system

輸送系統負責將待涂裝工件輸送到指定位置,其材質需具備足夠的強度、剛性和耐磨性,以承受工件的重量和輸送過程中的沖擊。

The conveying system is responsible for transporting the workpiece to be coated to the designated location, and its material must have sufficient strength, rigidity, and wear resistance to withstand the weight of the workpiece and the impact during the conveying process.

碳鋼/合金鋼:輸送鏈條、軌道等部件通常采用碳鋼或合金鋼材質。這些材質具有高強度、高剛性,能夠承受較大的載荷和沖擊,同時經過熱處理后,表面硬度和耐磨性得到提升,延長了使用壽命。

Carbon steel/alloy steel: Components such as conveyor chains and tracks are usually made of carbon steel or alloy steel. These materials have high strength and rigidity, and can withstand large loads and impacts. At the same time, after heat treatment, the surface hardness and wear resistance are improved, extending the service life.

尼龍/聚氨酯:在輸送系統的導向輪、支撐輪等部件中,尼龍或聚氨酯材質因其良好的耐磨性、自潤滑性和低噪音特性得到應用。這些材質能夠有效減少工件輸送過程中的摩擦和振動,提高輸送平穩性。

Nylon/polyurethane: Nylon or polyurethane materials are used in components such as guide wheels and support wheels in conveyor systems due to their excellent wear resistance, self-lubricating properties, and low noise characteristics. These materials can effectively reduce friction and vibration during the workpiece transportation process, and improve the smoothness of transportation.

4. 控制系統材質

4. Control system material

控制系統是機器人涂裝線的“大腦”,負責協調各部件的運動和參數控制。其材質需具備良好的電氣絕緣性、耐熱性和抗干擾能力。

The control system is the "brain" of the robot painting line, responsible for coordinating the motion and parameter control of various components. Its material needs to have good electrical insulation, heat resistance, and anti-interference ability.

工程塑料/金屬合金:控制柜、電氣元件等部件通常采用工程塑料或金屬合金材質。工程塑料具有良好的電氣絕緣性和耐熱性,能夠有效保護內部電路;金屬合金則具有較高的強度和剛性,能夠抵御外部沖擊和振動。

Engineering plastics/metal alloys: Components such as control cabinets and electrical components are usually made of engineering plastics or metal alloys. Engineering plastics have good electrical insulation and heat resistance, which can effectively protect internal circuits; Metal alloys have high strength and rigidity, and can resist external impacts and vibrations.

5. 安全防護裝置材質

5. Material of safety protection device

安全防護裝置是確保涂裝線安全運行的重要保障,其材質需具備足夠的強度、韌性和耐沖擊性。

The safety protection device is an important guarantee for ensuring the safe operation of the painting line, and its material needs to have sufficient strength, toughness, and impact resistance.

鋼化玻璃/有機玻璃:在觀察窗、防護罩等部件中,鋼化玻璃或有機玻璃因其良好的透明度、耐沖擊性和耐化學性得到應用。這些材質能夠有效防止涂料飛濺對操作人員的傷害,同時方便觀察涂裝過程。

Tempered glass/organic glass: In components such as observation windows and protective covers, tempered glass or organic glass is used due to its good transparency, impact resistance, and chemical resistance. These materials can effectively prevent paint splashing from causing harm to operators, while also facilitating observation of the painting process.

金屬網/金屬板:在防護欄、安全門等部件中,金屬網或金屬板因其高強度和剛性得到廣泛應用。這些材質能夠有效阻擋人員或物體進入危險區域,確保涂裝線的安全運行。

Metal mesh/metal plate: Metal mesh or metal plate is widely used in components such as protective barriers and safety doors due to its high strength and rigidity. These materials can effectively block personnel or objects from entering hazardous areas, ensuring the safe operation of the painting line.

綜上所述,機器人涂裝線各組成部分的材質選擇均經過精心考慮,以滿足不同的使用需求和環境條件。隨著材料科學的不斷發展,未來機器人涂裝線材質將更加多樣化、高性能化,為工業生產提供更加高效、穩定、安全的涂裝解決方案。

In summary, the material selection of each component of the robot painting line has been carefully considered to meet different usage needs and environmental conditions. With the continuous development of materials science, the materials used in future robot coating lines will become more diverse and high-performance, providing more efficient, stable, and safe coating solutions for industrial production.

本文由機器人涂裝線友情奉獻.更多有關的知識請點擊:http://www.gtjjw.cn我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.gtjjw.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

魯公網安備 37142502000144號

魯公網安備 37142502000144號